Fabricating 3D mesoscopic magnetic systems

3D magnetic nanostructures have recently attracted great interest due to the possibility to realize novel properties, the benefits for technological applications, such as high-density data storage, and the opportunities to deepen our understanding of magnetic interactions. While significant progress in nanofabrication has resulted in a flurry of architectures, a significant challenge remains, namely the controlled manufacture of high-quality magnetic materials on 3D surfaces.

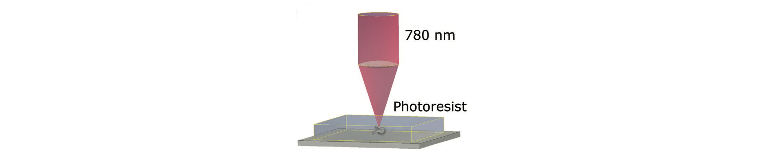

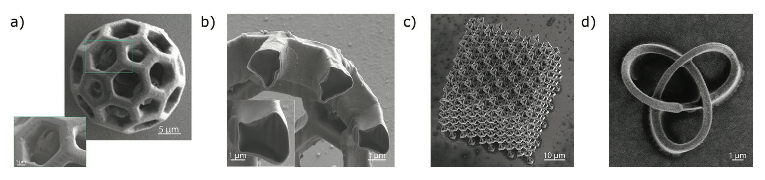

We have recently succeeded in realizing 3D nanostructures covered by a homogenous thin layer of magnetic material [1]. Starting from polymer microstructures fabricated with two-photon lithography, an advanced 3D printing technique (see Fig. 1), we achieved a homogeneous deposition of high-quality magnetic material on high gradient 3D surfaces using electroless deposition.

Electroless deposition consists of immersing a sample in an aqueous solution containing metals in the form of ions, a complexing agent and a reductant. The deposition takes place due to redox chemical reactions: as the reductant loses electrons as a result of oxidation, the metal ions (Ni–Fe in our case) are reduced by the freed electrons leading to the formation of a metallic film on the sample surface. The deposited film (thickness ≈ 70 nm) coats the scaffold with a homogeneous thickness.

Such an approach has enabled us to apply a magnetic coating (Ni–Fe) on polymer architectures of different shapes, as shown in Fig. 2, and in all cases a smooth, homogeneous deposition over the surface of the 3D structures can be observed.

The next step will be to determine the magnetic configurations in the 3D structures, which is of interest because of potential to realize a 3D artificial spin ice lattice or structures with topological properties.

References

- Electroless Deposition of Ni–Fe Alloys on Scaffolds for 3D Nanomagnetism

P. Pip, C. Donnelly, M. Döbeli, C. Gunderson, L.J. Heyderman, L. Philippe, external page Small 16, 2004099 (2020)